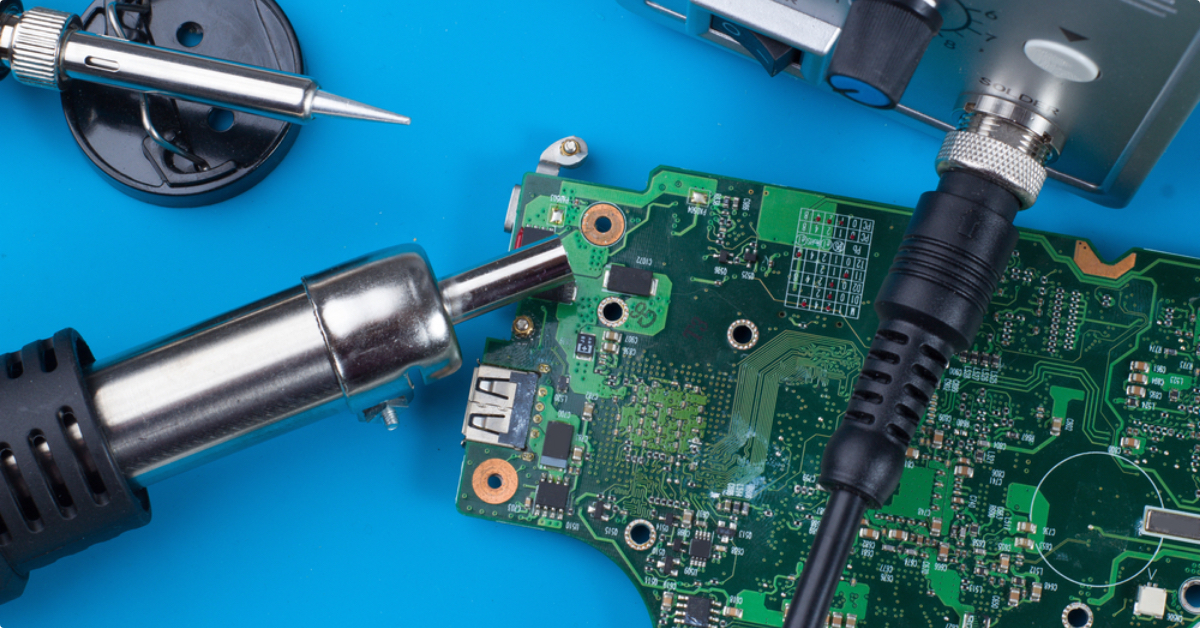

PCB

Designing a PCB (printed circuit board) for car and boat electronics involves several steps, including:

Define the requirements: Determine the specific requirements for the PCB, including the electronic components that will be used, the size and shape of the PCB, the operating conditions, and any safety or regulatory requirements.

Create a schematic: Create a schematic diagram of the PCB, which shows the electrical connections between the components. This step is crucial to ensure that the circuit will work as intended and to identify any potential issues.

Layout the PCB: Using special software, layout the PCB. This step involves placing the components on the PCB and routing the electrical connections between them. The PCB layout is a critical step, as it affects the performance, reliability, and cost of the PCB.

Generate Gerber files: Gerber files are a type of file used to communicate PCB designs to manufacturers. These files include information such as the PCB layout, the location of components, and the routing of connections.

Check the PCB design: Use design verification software to check the PCB design for errors and to ensure that it meets the requirements.

Fabricate the PCB: Send the Gerber files to a PCB manufacturer to fabricate the PCB.

Test and debug: Once the PCB is fabricated, test and debug.

The process of testing and debugging a PCB (printed circuit board) typically involves several steps, including:

Power-on testing: This initial test verifies that the PCB has power and that it is functioning properly. This test can be done by measuring the voltage at various points on the PCB, and checking for any shorts or open circuits.

Functional testing: This test verifies that the PCB is functioning as intended. This step will include connecting the PCB to any necessary equipment and writing test code to validate that the PCB works as it was designed to.

In-circuit testing (ICT): This test is used to verify that the components on the PCB are functioning correctly and that they are properly connected. ICT is done by connecting a test probe to each component on the PCB and measuring the electrical characteristics, such as resistance and capacitance, to ensure they are within the specified tolerances.

Environmental testing: Environmental testing simulates the conditions the PCB will be exposed to, such as temperature, humidity, vibration, and shock, to ensure that the PCB can withstand the conditions it will be exposed to.

Debugging: If any issues are found during testing, debugging is necessary. This step involves identifying the cause of the issue and making the necessary changes to fix it. This can include reworking the PCB, replacing components, or modifying the firmware or software.

Initial consultation: Meet with the client to understand their business needs, goals, and target audience for the frontend. Identify any constraints or requirements that need to be taken into account.

Firmware and software are two distinct types of programming that are used in conjunction with a PCB (printed circuit board).

Firmware is a type of low-level software that is stored on a chip, such as an microcontroller or microprocessor, that is physically located on the PCB. Firmware is responsible for controlling the hardware of the PCB and interacting with any connected sensors or actuators. It is typically written in a low-level programming language such as C or assembly, and is closely tied to the hardware.

Software, on the other hand, is a higher-level program that runs on a separate device, such as a computer or a mobile device, and interacts with the firmware. It provides a user interface, data logging and communication protocols, and other functionalities. Software is typically written in higher-level languages such as Python, C++, Java, and so on.

In general, firmware controls the hardware and provides an interface for the software to interact with it. This is essential for the PCB to function properly and for the software to be able to control and monitor the hardware. Firmware and software work together to provide the functionalities required by the PCB, as well as providing a user interface and/or communication with other systems.

Apps

Image ACE